Solutions

Safety Audits

Electrical Safety Audits as per IS 14489 & IS 732

Thermography

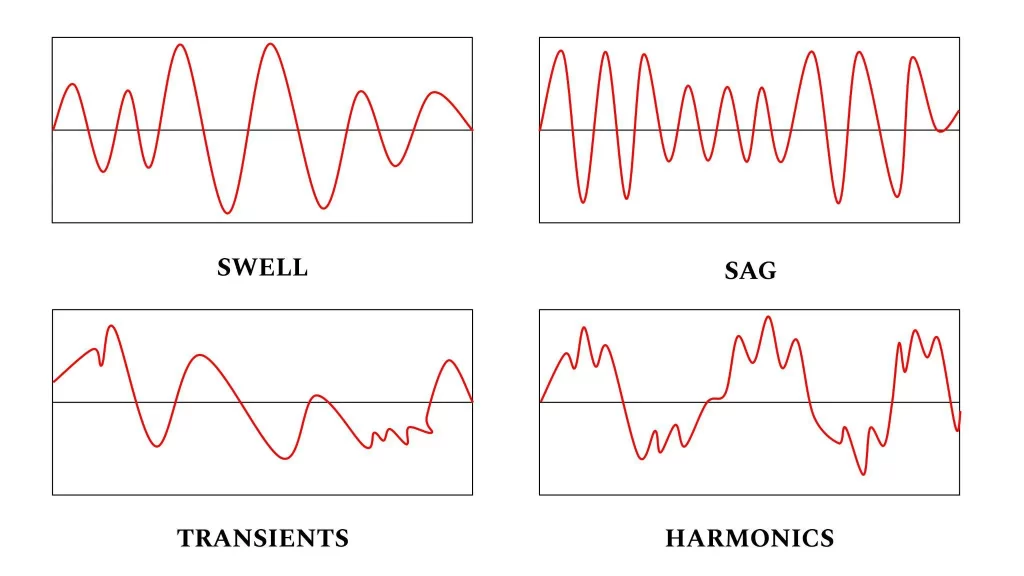

Power Quality Analysis

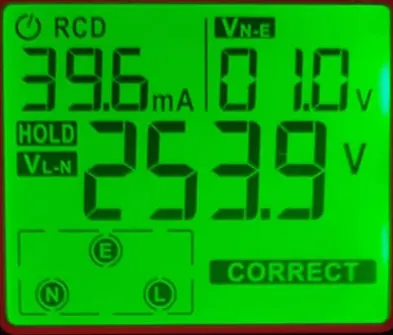

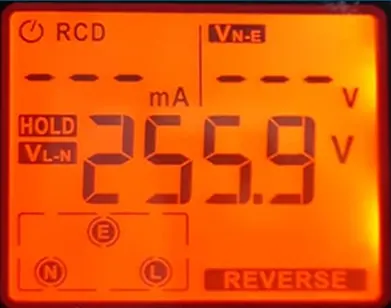

Earthing Verifications

The earth connection of this socket is properly connected.

The earth connection of this socket is not properly connected.

Lightning arrester verifications

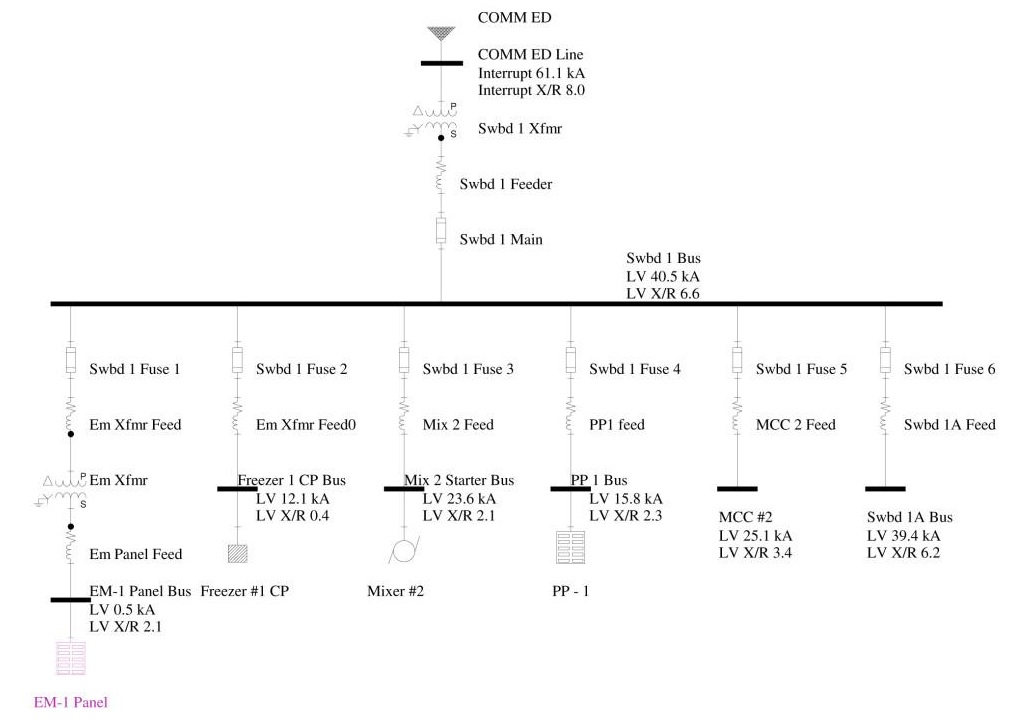

SLD verification

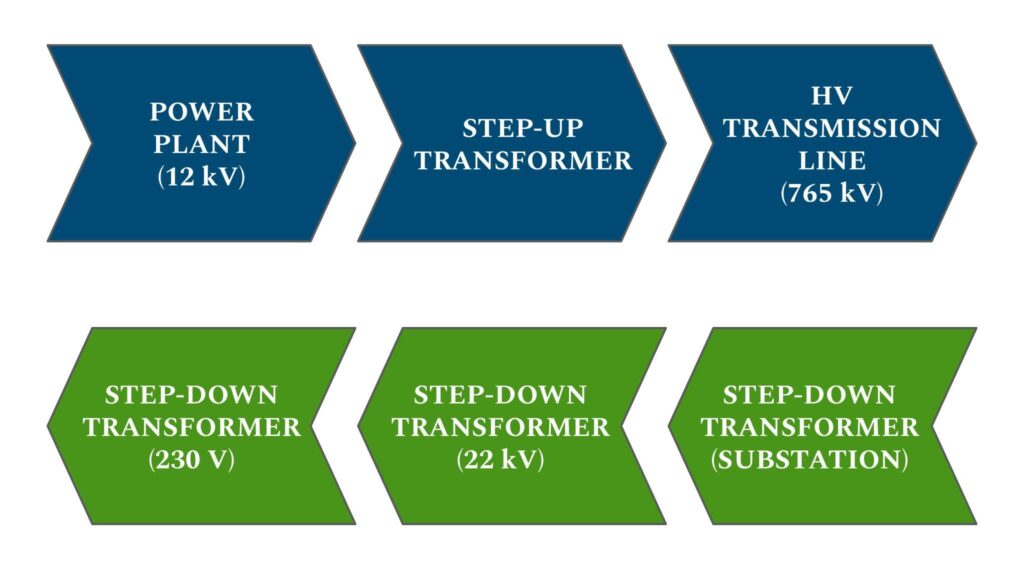

Single line diagram verification of electrical systems, as per Indian Standards, is a critical process for ensuring the accuracy and reliability of electrical system designs. According to IS 732 and IS 13947, this verification involves reviewing the single line diagram to confirm that it accurately represents the electrical distribution system’s layout, including all components such as breakers, transformers, and load connections. The process ensures compliance with safety regulations and operational efficiency by validating that the diagram matches the actual system configuration and meets the required standards for protection, coordination, and functionality. Proper verification helps prevent potential issues and enhances the safety and performance of electrical installations.

Load Flow Study

ARC Flash Study

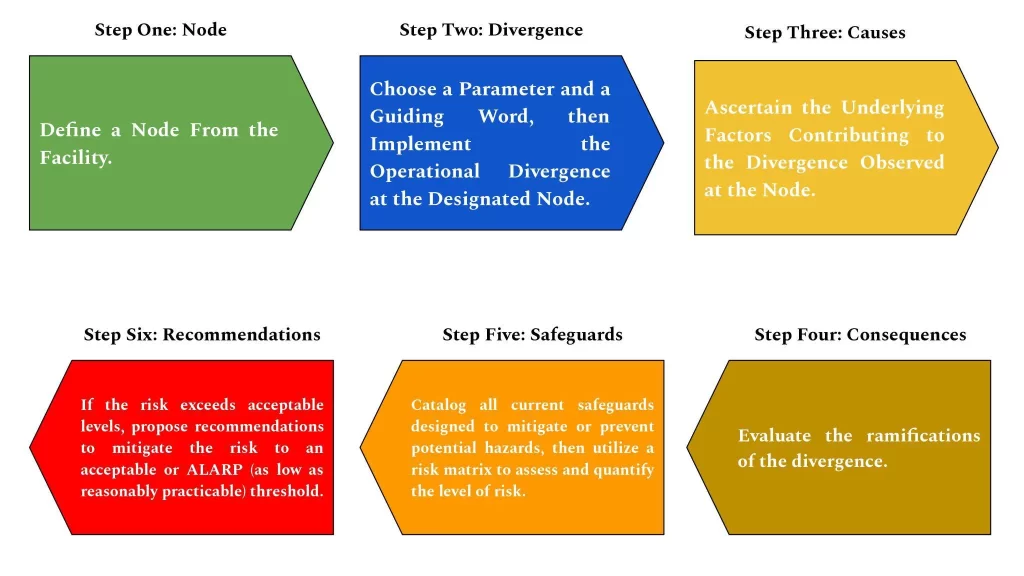

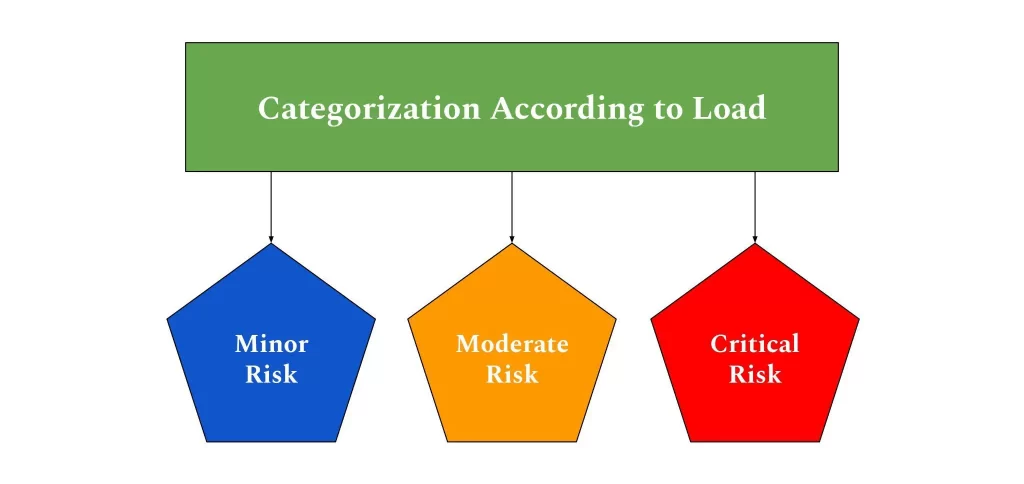

RISK Assessment & HAZOP Study

Fire Load Calculations

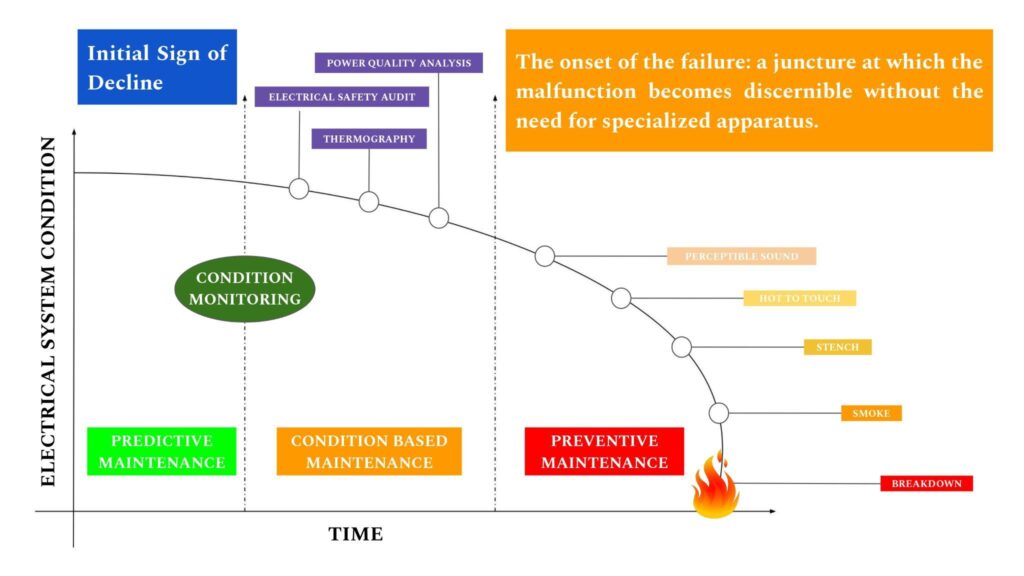

Condition Monitoring

Earthing Resistance Test

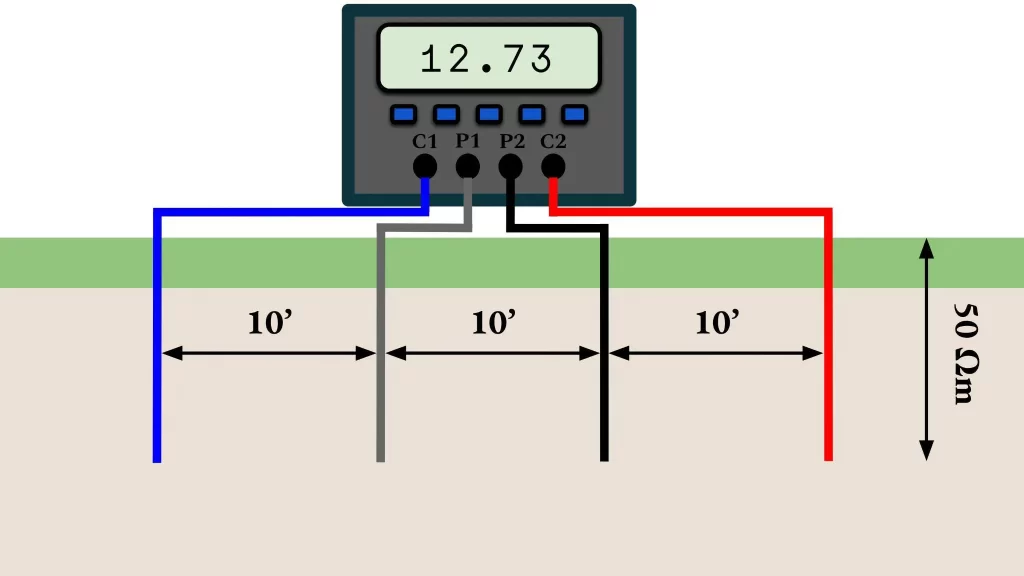

Soil Resistivity Test

Address

Y. K. Nagar NX Virar West

Contact Numbers:

+91 89563 03501

+91 89563 03502